Economiser

Energy saving and efficiency are key factors for modern industry. One of the most significant energy users in a typical production facility is the steam boiler and, therefore, investing in energy saving equipment should always provide a very good return on investment.

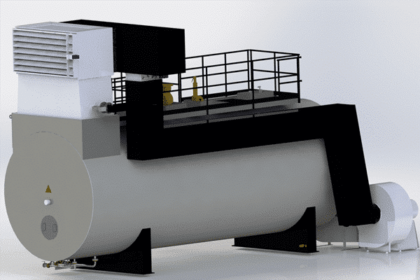

Using its extensive expertise in energy efficiency and boiler design and optimisation, Babcock Wanson offers a broad range of exhaust gas economisers perfectly matched to the boiler to which they will be fitted. These economisers recover heat from the exhaust gas to, typically, the boiler feed water thereby optimising the overall efficiency of the plant in the most compact and cost-effective manner.

These advanced and robust economisers can significantly increase the boilers efficiency often so much so that the return on investment can be as little as one year. More than 400 Babcock Wanson economisers have been installed on existing boilers.

Calculating your Capital Gain

Babcock Wanson economisers can be designed to work with both fixed and interruptible natural gas supplies thereby removing the need for costly and often complex exhaust gas bypass systems for the majority of installations.

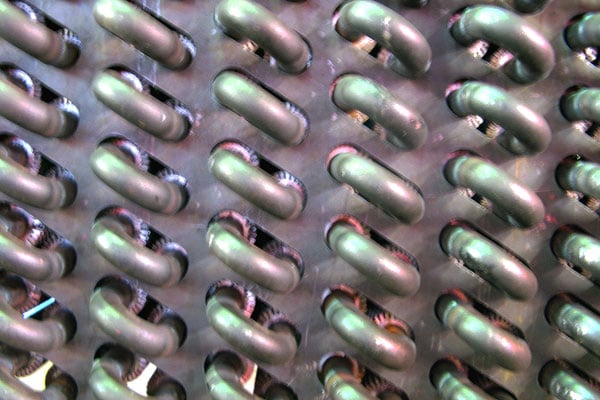

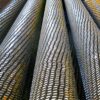

Construction: All Carbon Steel or Stainless Steel (depending on equipment type)

Operating Conditions

- Maximum Boiler Design Pressure: typically, 28 bar.

- Maximum exhaust gas temperature: 300 ° C.

- For Natural Gas fired boilers the water temperature entering the economiser must be ≥ 60 ° C. This typically provides an efficiency gain of 5-6%.

- For Gas Oil fired boilers, the water temperature entering the economiser must be ≥ 105 ° C; Efficiency gain of typically 5%. Continuous operation of up to 350 hours is possible after which cleaning of the exchange surfaces with air or steam may be required.

Babcock Wanson can offer a 5-year guarantee for the economisers on condition that the burner maintenance and the boiler feedwater treatment are covered by a Babcock Wanson maintenance and water treatment contracts.

Economiser Heat Recovery Systems

| Economiser type | Exhaust Gas Economiser mounted in drawer in the back box of the boiler | Economiser mounted in casing on the smoke outlet | Exhaust Gas Economiser plus feed water exchanger | Exhaust Gas Economiser plus fumes/water/combustion air exchanger |

|---|---|---|---|---|

| Conditions of application | Natural Gas only | Natural Gas / Gasoil, For mixed applications | Use in conjunction with a Thermal Deaerator and where there is a cold source, e.g. incoming treated water, and a condensate return rate <50% | Process with 85 to 90% condensate return, and a steam output greater than 15 t/h |

| Yield gain | 4 to 5% | 5 to 6% | 5 to 6% | Depending on operating conditions |

| Typical return on Investment * | Less than 1 year | Less than 1 year | Less than 3 years | Less than 3 years |

* These values are strictly dependent on the boiler operating conditions.