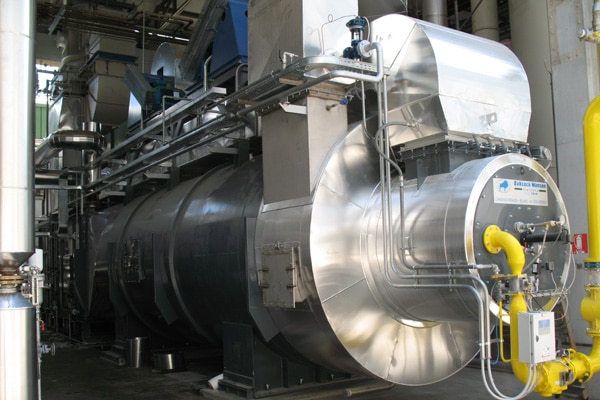

Recuperative Oxidisers

Recuperative Oxidisers are targeted at industrial process where there is a combination of energy demand and effluent oxidation. These types of Thermal Oxidisers are mainly suitable for higher VOC concentrations and lower effluent flow rates.

Operating Principle

Pollutant gases are heated to high temperature – typically in excess of 800°C – in a combustion chamber for 0.6 – 2.0 seconds to fully oxidise them before being discharged to the atmosphere. Using Heat Recovery units, energy is recovered from the exhaust stream for reuse in the process or elsewhere, thereby reducing total operating costs.

Recuperative Oxidiser plant typically includes:

- An inverter controlled effluent transfer fan

- A pre-heater for the effluent air

- The Oxidiser

- Control panel for system regulation with PLC and operator interface panel (HMI)

- Heat recovery units which can recover heat into thermal fluid, steam, hot water or high temperature pressurised water and/or air

Advantages of Recuperative Oxidisers

- Continuous control of emissions

- Simplicity of control and management

- Quick start up

- High energy recovery

- Safety and reliability with full hazard audit

- Range of effluent 500 to 30,000 Nm³/h